Midwest Funding Solutions

In Partnership with 7 Figures Funding

Part 1 of 4 Series on Concrete Innovations

—Sensor Embedded Concrete—

How wireless curing sensors improve quality, safety, and real-time decisions

Leading construction teams and precast operators are already embedding wireless sensors into their pours—and doing it with precision.In a Purdue University infrastructure project, engineers attached curing sensors directly to rebar before concrete placement, allowing real-time monitoring of internal temperature and strength throughout the curing cycle.Similarly, in Hilti’s training guide, crews are shown securing sensors with cable ties to rebar—ensuring the sensor remains positioned beneath no more than 8 inches (≈200 mm) of concrete to ensure accurate signal transmission. This practice is becoming an industry standard for teams that want digital assurance of their curing performance—without destructive testing.

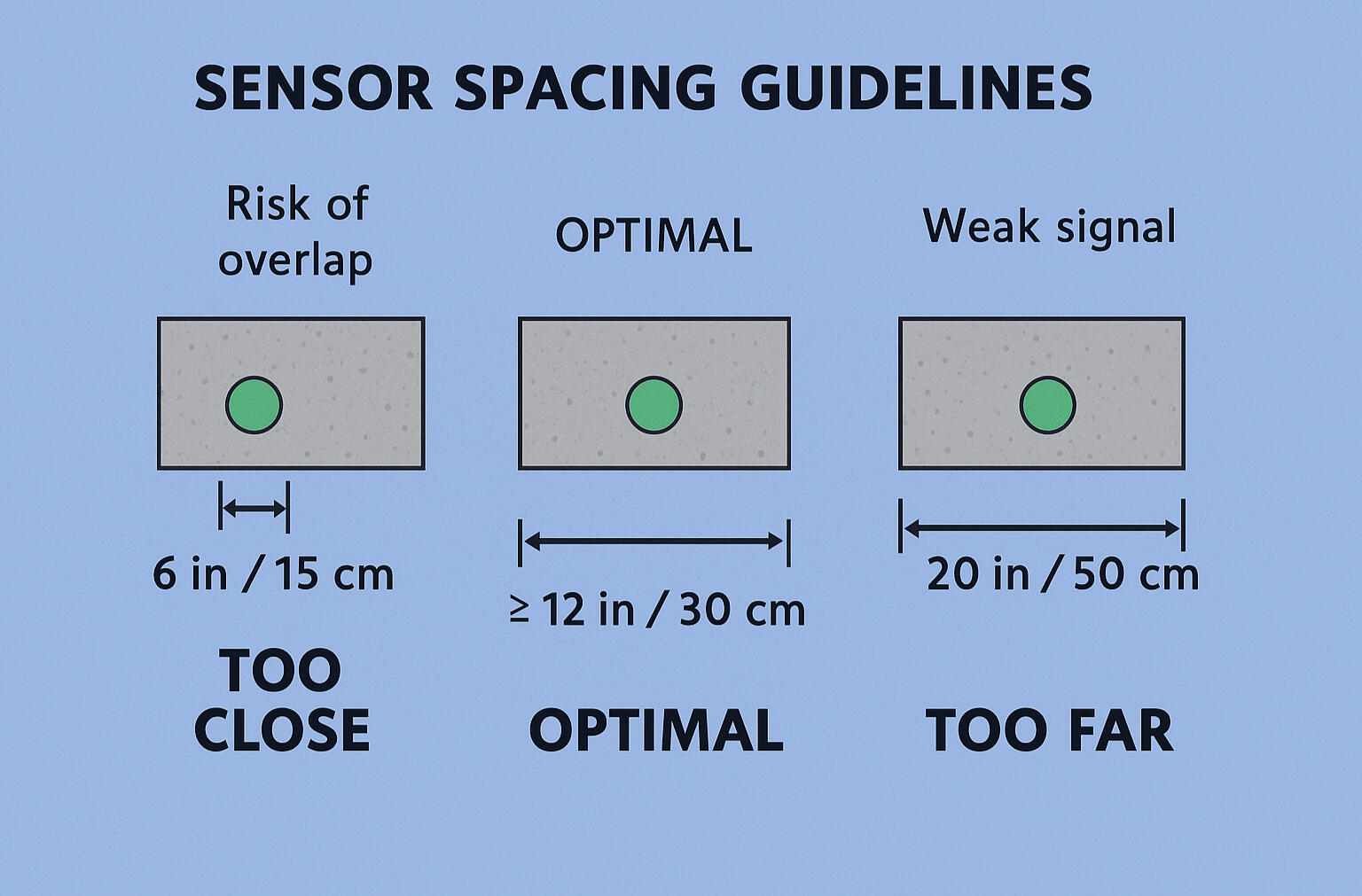

Sensor Spacing Guidelines

When embedding wireless curing sensors in concrete, proper spacing is crucial for accurate, representative data collection across a pour.Sensors should be spaced evenly and placed in areas where temperature and strength readings are most critical—typically at mid-slab depth and near structural reinforcements.

For large slabs or pours exceeding 20 feet (6 meters) in any direction, sensors should be placed no more than 10–15 feet (3–4.5 meters) apart to account for thermal gradients and curing variations.In vertical pours such as columns or walls, sensors are often staggered at different elevations to track curing at multiple heights. Following consistent spacing standards ensures that crews can detect anomalies, confirm uniform curing, and avoid costly delays or over-engineering.

Text Sources

Supporting data and recommendations based on:SmartRock Sensor Installation Guidelines (Giatec Scientific)ASTM C1074 - Maturity Method for Concrete StrengthNPCA Resources on Precast Quality and CuringHow to Install SmartRock Concrete Sensors – YouTube

Do You Know?

QUIZ 1

What is the maximum amount of concrete cover typically recommended above an embedded curing sensor?

QUIZ 2

What is a typical weight range for modern concrete curing sensors?

Quiz 3

Which of the following is a key advantage of using wireless sensors for performance monitoring?

A. 2 inches (≈50 mm)

B. 4 inches (≈100 mm)

C. 8 inches (≈200 mm)

D. 10 inches (≈250 mm)

A. Less than 1 oz (≈28 g)

B. 2–3 oz (≈57–85 g)

C. 6–8 oz (≈170–225 g)

D. Over 1 lb (≈450 g)

A. Reduces the need for concrete mix design

B. Allows for real-time data reporting and early problem detection

C. Eliminates the need for all on-site personnel

D. Increases required cure time

—Why Depth Matters—

Why Sensor Size and Weight Matter in precast Workflows

When it comes to embedding sensors into precast concrete elements, size and weight aren’t just technical specs—they’re part of what makes the entire process practical and efficient on-site.Most wireless concrete sensors, like the SmartRock or Maturix probes, are compact and lightweight—often smaller than a deck of cards and weighing less than a smartphone. This minimal profile means installation crews can quickly strap sensors to rebar using simple cable ties, without needing to adjust reinforcement layouts or worry about shifting balance during lifting and handling.In a busy precast yard, every second counts. A bulky sensor would complicate mold setup, clash with embedded hardware, or even require changes in lifting anchor placement. Lightweight sensors eliminate those headaches. Their small footprint helps maintain a smooth workflow—just secure, pour, and go.From a structural planning perspective, size also plays into signal reliability. Sensors typically need to be embedded no deeper than 8 inches (200 mm) to maintain a reliable Bluetooth or wireless signal. Designers must consider this when specifying concrete cover or determining how far from surface faces to place the rebar. Fortunately, most modern sensors offer long enough cable leads (1 to 10 feet) to allow flexible placement while keeping the transmitter near the surface.Bottom line? Choosing a small, lightweight sensor makes integration seamless—whether you’re fabricating hundreds of panels a week or monitoring an architectural pour on-site. It’s a small detail that saves big on coordination, labor time, and signal headaches.

“In precast, efficiency is everything. If your sensor adds weight, space, or complexity—you’re already behind schedule.”

— Lead Field Engineer, National Precast Association

—Performance Monitering—

“On a large bridge pour, crews used embedded IoT-enabled maturity sensors and synchronized data with cloud dashboards. This allowed them to make precise curing decisions, reducing over-curing time by 25% and cutting daily inspection visits in half.”

Modern wireless sensors don’t just measure temperature—they track temperature, relative humidity, and even strength maturity in real-time, accessible directly from a smartphone or cloud dashboard. This live data helps team leaders catch pump, pour, or curing issues before they turn into costly delays or structural problems

Why That Matters for Your Team:

Early Warning = Big Savings

Objective Data Speeds Decisions

Quality You Can Prove

How It Fits Into Your Workflow

Consider it a smart assistant: on-site sensors feed data to your phone, which tracks curing 24/7—even overnight. That means less manual tracking, fewer field calls, and more efficient crew scheduling around fact-based milestones, not assumptions.

Sensor Readiness Checklist

IS YOUR

COMPANY

"SENSOR READY"?

If you’re considering adding smart sensors to your toolkit, this quick readiness checklist will help you assess your next move.

🔧 Project Type Fit:

You frequently work with pours where temperature or curing strength directly affects scheduling, safety, or quality outcomes.🧰 On-Site Tech Capable:

Your team has access to basic smartphones or tablets for sensor syncing, scanning, or app-based monitoring.🧠 Data Willingness:

You’re ready to use sensor data (temperature, humidity, maturity, etc.) to guide decisions rather than just relying on tradition.📡 Connectivity Options:

You have at least intermittent access to cellular or Wi-Fi for syncing with cloud platforms (or plan to monitor offline).👷 Team Buy-In:

Your foremen or field teams are open to quick sensor training and recognize the value of real-time data alerts.📋 Budget for Value:

You can invest in a few initial sensors (typically priced per project) with the expectation of long-term ROI from fewer delays and less rework.

Are You Ready to Embed Smart Sensors in Your Workflows?

In an industry where timing, precision, and accountability can make or break a project, integrating wireless sensors isn't just about following trends — it’s about unlocking smarter, more profitable operations.Contractors and precast teams who embrace embedded monitoring gain real-time insights, reduce rework, and differentiate themselves in an increasingly competitive market.

Midwest Funding Solutions can connect you with the funds you need to make embeded sensors part of your company's innovative processes.

Scan the QR code or follow the link to get pre-approved and start your funding process within 48 hours

Quiz Answers

Quiz 1C. 8 inches (200 mm)

This depth ensures sufficient concrete coverage for reliable temperature and curing readings while avoiding signal interference.

QUIZ 2B. 2–3 oz (≈57–85 g)

This lightweight design minimizes strain on rebar ties and allows easy integration into standard pour workflows—without shifting during placement.

QUIZ 3

B. Allows for real-time data reporting and early problem detection

Real-time temperature and humidity feedback helps crews respond quickly to anomalies—such as cold spots or premature drying—avoiding costly rework or strength loss.

Part 2 of 4 Series on Concrete Innovations

—AI Optimized Mix Design—

Part 3 of 4 Series on Concrete Innovations

—Advanced Digital Fabrication—

Part 4 of 4 Series on Concrete Innovations

Smart Site Tools and Drone Tech